Sustainability of Wooden Utensils: The Environmental Benefits

Single-use plastics represent a real, long-term risk for the environment and humans. Disposable wooden utensils are a sustainable alternative. They are a way for consumers and businesses to significantly reduce the world’s reliance on single-use plastics.

In the U.S. alone 40 billion individual plastic utensils are used every year. This is just a small part of the over 27 million tons of plastic that enters U.S. landfills every year. Single-use plastics have been deemed an environmental risk by the United Nations and other respected international agencies. Not only does their production contribute to climate change, but their long-term environmental effects are not yet fully understood. Over time they breakdown into smaller “micro-plastics,” which are consumed by living organisms. Already, humans consume on average between 39,000 to 52,000 “micro-plastics” every year.

Disposable wooden utensils are a sustainable way to reduce our reliance on plastics, particularly in the restaurant industry. They use less resources, produce less byproducts, and create less waste than single-use plastics. Additionally, when produced with a robust supply chain they are cost competitive with plastic and project an environmentally conscious image for restaurants. This is a key part of capturing the growing market of consumers that prefer environmentally conscious businesses.

Resource Use for Disposable Wooden Utensils

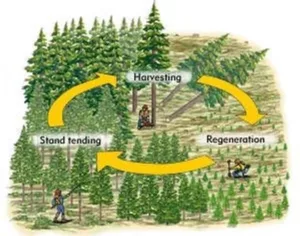

Single-use plastics require large resource inputs and are heavily reliant on oil and fossil fuels. Disposable wooden utensils take a more sustainable approach to production. Birch and bamboo are two of the most common types of wood used. Both are relatively fast growing trees, so they can be planted for the sole purpose of harvesting. This allows old-growth and other natural forests to remain intact, protecting biodiversity. Currently over half of the world’s natural forests have been cut down.

Replanting trees on land already deforested protects the remaining forests while providing the timber resource we need.

Replanting trees on land already deforested protects the remaining forests while providing the timber resource we need.

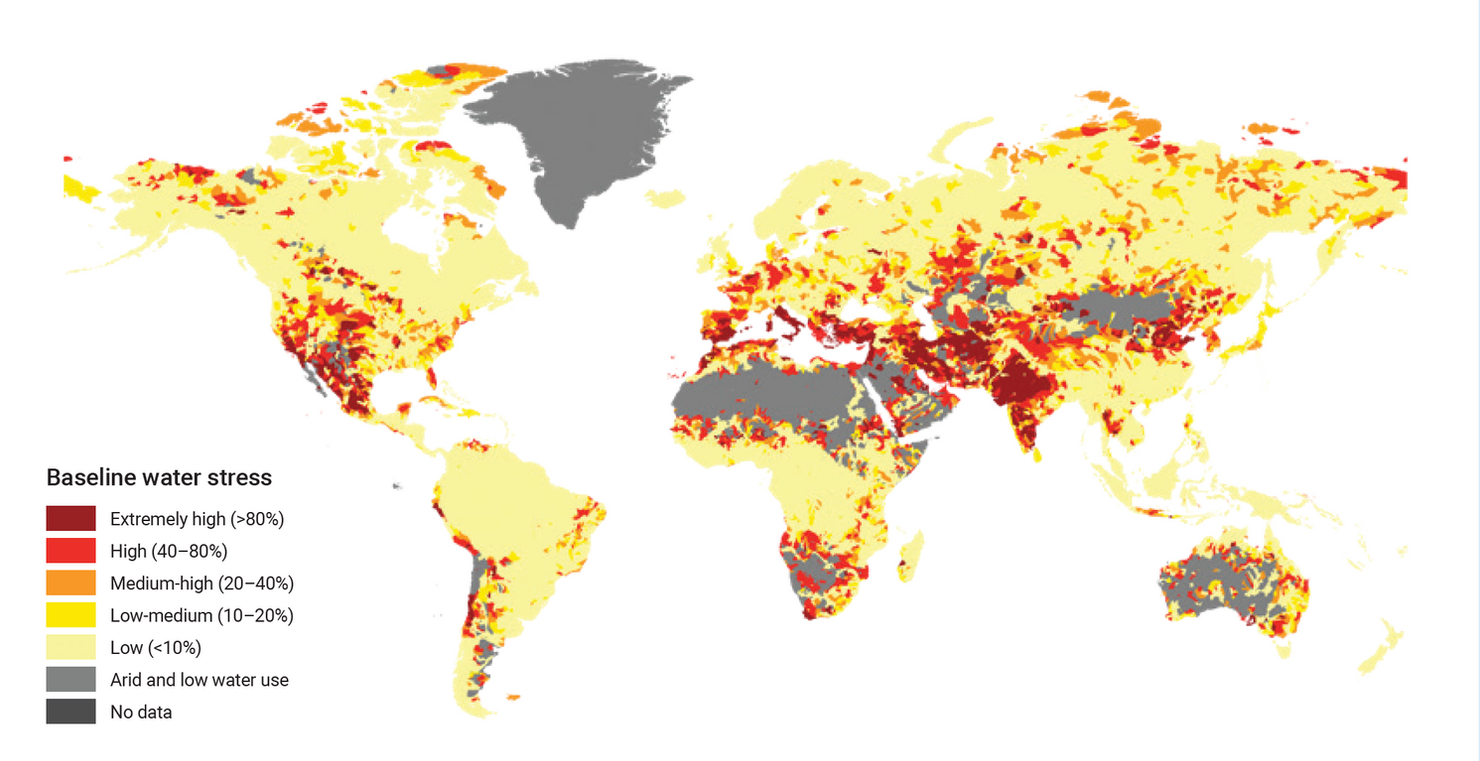

The two main resource inputs used in the production of disposable wooden and plastic utensils are water and energy. For wooden utensils the majority of water is used in growing trees and processing. Trees require a large amount of water to grow, which they use for processes like photosynthesis. But unlike in plastic production a majority of this water, around 99%, actually reenters the atmosphere through transpiration. Only 1% of the water used for growing trees is actually taken out of the ecosystem. This plays a major role in the sustainability of wooden utensils.

Processing also requires water, but at a much smaller scale than producing plastic. This is because processing disposable wooden utensils is a relatively simple process. It doesn’t require specific environmental conditions, like making plastic does. When done in an efficient way the total amount of water used in producing wooden utensils is over 99% less than required to produce plastic utensils. This equates to over 12 gallons of water saved for every pound of utensils made of wood instead of plastic.

Water is an extremely valuable resource and is expected to become even more valuable in the coming years. The United Nations predicts that 52% of the world’s population will be affected by water scarcity in 2050. This means that 4 billion people will not have access to adequate quantities of clean water. Reducing water use in industry is a key step in dealing with future water requirements.

The other main resource input is energy. Energy is required for planting, maintaining, harvesting, and processing wood. These processes do require significant energy inputs, but they are much lower than those required for plastic. The difference ranges from 4 to 32 MJ of energy per pound of utensils made.[3] This range is based on the type of plastic or wood used and production method. Lower energy requirements translates to a host of environmental benefits that add to the sustainability of wooden utensils. These benefits range from decreased climate change impacts to less pollution.

Byproducts from Disposable Wooden Utensils

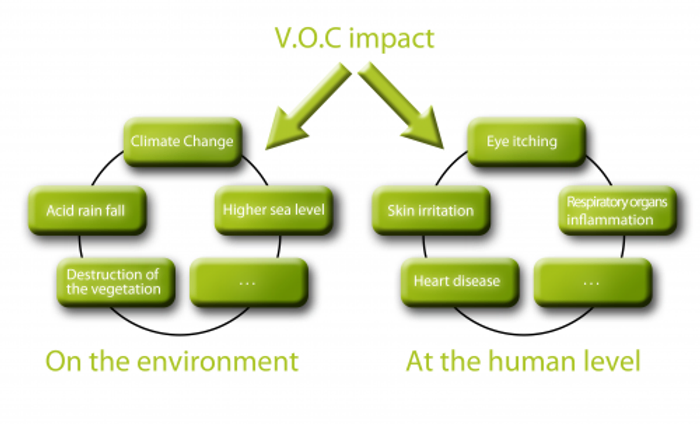

As with all manufacturing there are multiple byproducts created during production. For disposable wooden and plastic utensils the largest byproduct waste stream is air. The two major types of pollutants released into the air are volatile organic compounds (VOCs) and carbon dioxide (CO2). VOCs are organic compounds like methane and benzene. In air they react with nitrogen oxides to produce harmful tropospheric ozone. Not only does tropospheric ozone contribute to climate change, but it has been linked to multiple respiratory health issues.

VOCs are primarily produced from burning and processing fossil fuels. The lower energy requirement for the production of disposable wooden utensils means less VOCs are released. Because the amount of energy needed in production is so variable it is challenging to assign a single value to this difference. The best we can do is compare VOC release rates without considering their energy needs. Beyond energy the production of wooden utensils does not release any additional VOCs. The production of plastic utensils still does release VOCs because plastic is produced directly from oil. The processing of oil into plastic releases between 0.6 to 36.8 grams of VOCs per kilogram of product.

VOCs are much more potent than CO2, but much larger quantities of CO2 are produced for both disposable wooden and plastic utensils. The production of one ton of plastic utensils produces between 1350 to 3800 pounds of CO2 more than disposable wooden utensils. For comparison, an average passenger car produces one pound of CO2 per mile driven. This difference is massive, for each ton of utensils made of wood instead of plastic we save the amount of CO2 produced by a car driving across the entire U.S.

The total impact of both VOCs and CO2 on global warming is summed using the measurement of global warming potential (GWP). The GWP for wooden utensils ranges from -45 to 12, where the GWP of plastic utensils is between 0.5 and 3.3. Wooden utensils can actually have a negative GWP because wood absorbs and stores CO2 from the atmosphere. Depending on how the wooden utensils are disposed of, in a landfill or composted, determines how much CO2 is released directly back into the atmosphere. From this comparison it is clear that the sustainability of wooden utensils is much greater than single-use plastic.

Sustainable Disposal of Wooden Utensils

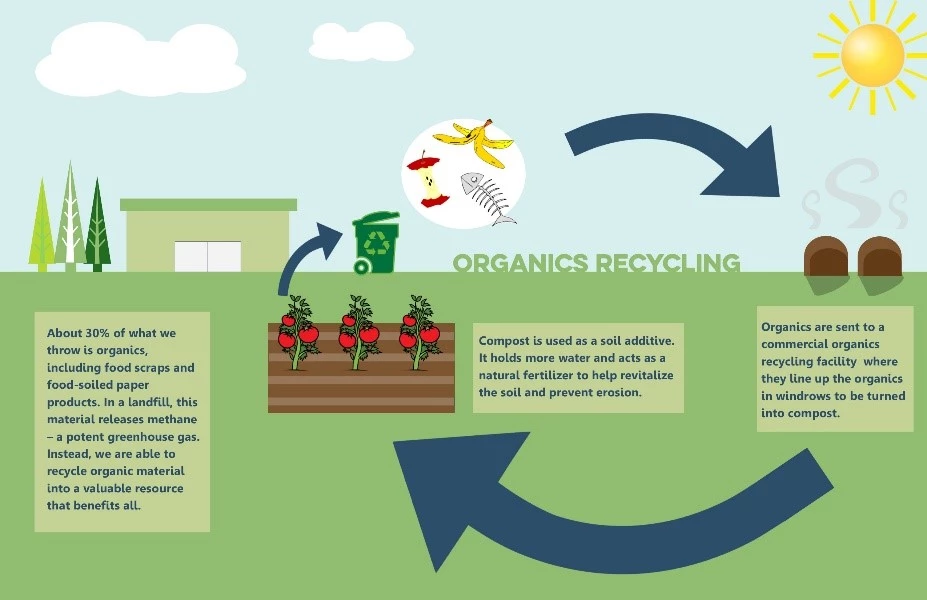

One of the main sustainability benefits of disposable wooden utensils is that they can be composted. Composting ensures that a majority of the carbon and nutrients stored in wood gets reused in soil and plants. This means less carbon dioxide is released into the atmosphere and the nutrients are recycled. Disposable wooden utensils can be composted in both home composting and commercial composting systems. This makes it easy for restaurants and customers to efficiently dispose of them.

In the worst case, if consumers don’t compost wooden utensils they are sent to a landfill. In landfills wooden utensils still decompose, but take longer. Depending on landfill conditions this can range from a few weeks to a few decades.

Single-use plastics cannot be composted, so they are sent directly to landfills. In landfills they take up to 1000 years to fully decompose. This causes a host of problems as plastic builds up in landfills over time. To meet these increasing waste storage demands new landfills have to be made. Additionally, plastic can leach toxic compounds, so landfills require careful monitoring or risk contaminating local ecosystems.

Benefits for Your Company

For restaurants, switching from single-use plastic to disposable wooden utensils provides more than just positive environmental impacts. A study by the global market research firm Nielson found that 66% of consumers were willing to pay more for products that come from companies who are committed to positive environmental change. This is up from 33% of consumers in 2010. This study is just one example of a variety of similar studies that have come to the same conclusion. It is clear that there is value in the sustainability of wooden utensils and a public demand for environmentally conscious businesses.

The Bottom Line

Disposable wooden utensils can help capitalize on this public sentiment and Alder-Tek manufacturing is positioned to help restaurants make this transition. We provide high quality birch and bamboo utensils that are cost competitive with single-use plastics. Additionally, our 30 plus years of manufacturing experience has facilitated our development of a robust supply chain with the capacity to meet the demand of mid and large scale restaurant businesses.

Beyond supplying our customers with high quality disposable wooden utensils, we also care about our environmental impacts. We are committed to being responsible stewards of every part of the supply chain. Our raw materials are Forest Stewardship Council Certified, our hiring and management policies exceed industry ethical standards, and our products are the safest and highest quality available today.

To find out more about Alder-Tek Manufacturing, our products, or request a sample, please Get in Touch.